Projets:Perso:2018:KAPEX KS120 DadoCutFunctionEnhancement

| : Modify / enhance the dado cut adjustment span of the FESTOOL Kapex KS120 miter saw | |

|---|---|

| Auteur | Eric |

| Date de proposition | August 2018 |

| Tags du projet | FESTOOL KAPEX KS120,dado cut,rainure,modding,enhancement |

| Utilisateur final | my Kapex |

| Type de projet

Projet personnel de Eric | |

|

Mod for FESTOOL KAPEX KS120 MITER SAW Augmentation de la plage de réglage de la fonction de découpe de rainure de la scie à onglet FESTOOL KAPEX KS120

|

Contents

Dado cuts height adjustement feature

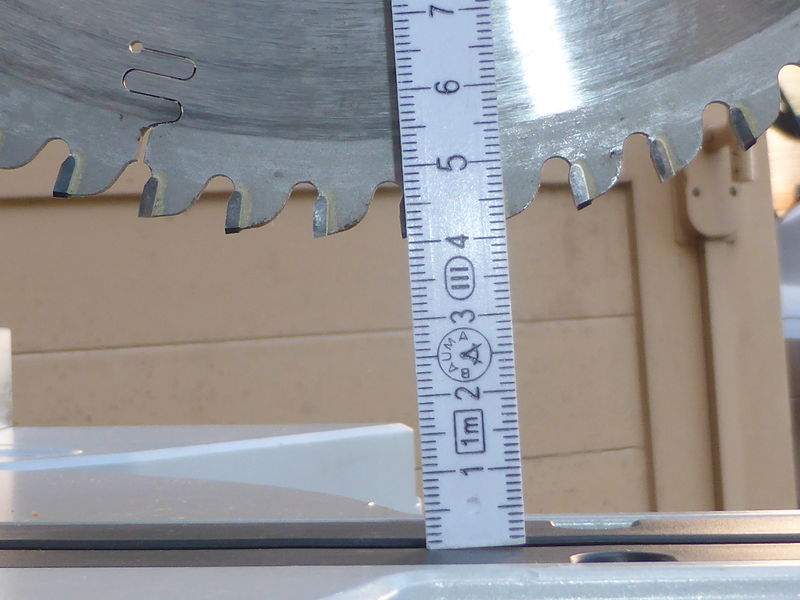

The Kapex KS120 height adjustement for dado cuts is limited to about 40 mm, which avoids using this feature for high workpieces. This limitation seems to annoy other Kapex users.

Ron Paulk recorded a small video to show how to perform dado cuts using the Kapex KS120. Many thanks to him !

User's manuals

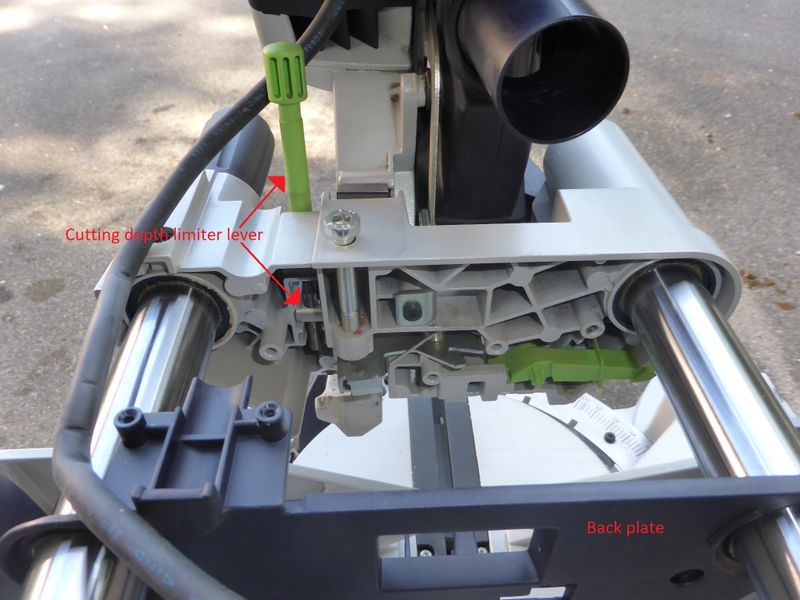

The cutting depth limit lever is referenced at position "1.4" on page 4 of the PDF user manual.

The cutting depth limit lever is referenced at position "U" on page 7 of this very nice official Kapex KS120 supplemental user's manual.

Enhancement

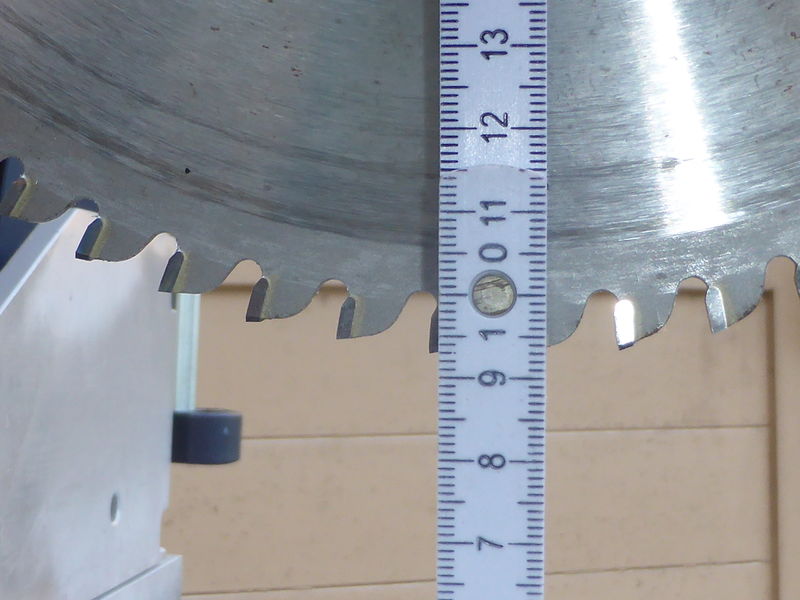

I updated my Kapex KS120 to allow a cutting depth limit adustement from 0 to ...93 mm

How to ?

Replace the existing cutting depth limiter lever with a custom made part.

To unmount the existing 1.4 lever, remove the mains cable strain relief and the machine back panel/plate.

As shown in the picture below, the cutting depth limiter lever is of easy access.

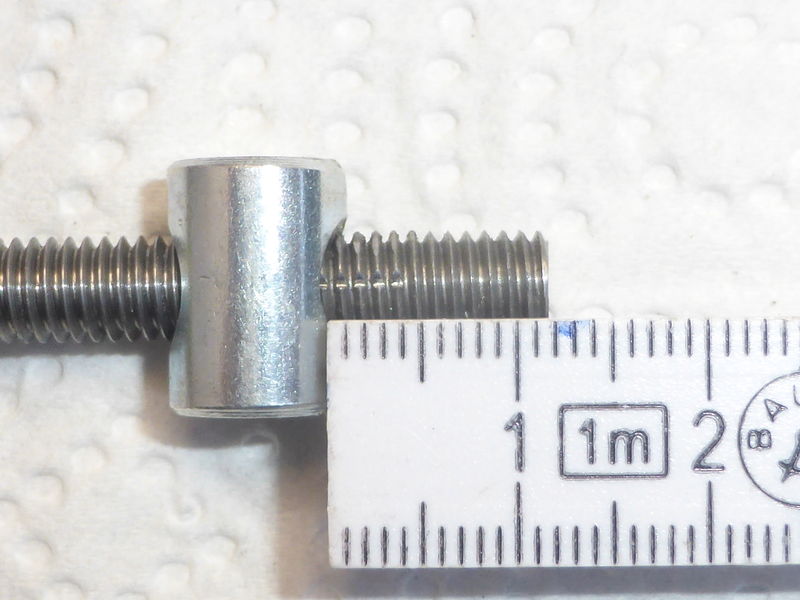

On a lathe, process a 6 mm silver steel rod or similar to make a modified copy of the lever 1.4 using the dimensions shown in the picture below (scale = mm). The shape of the thinner side of the rod does not need to match exactly with the original part.

Use an M6 x 1 mm (right hand) HSS die to machine the thread.

e.g ref. SDEMM06B here.

The total lenght of the new custom lever should not exceed 11,5 cm, as shown in the picture above.

Use an angle grinder to create the two flats on the opposite side of the thread.

Mount the barrel nut on the threaded side of your custom made lever

As you can observe on the original part, the lowest possible position of the barrel nut is 12 mm.

On your custom made lever, use a small chisel to break the thread at 3 or 4 locations in order to limit the barrel nut lowest position to 12 mm (same value as on the original Festool part).

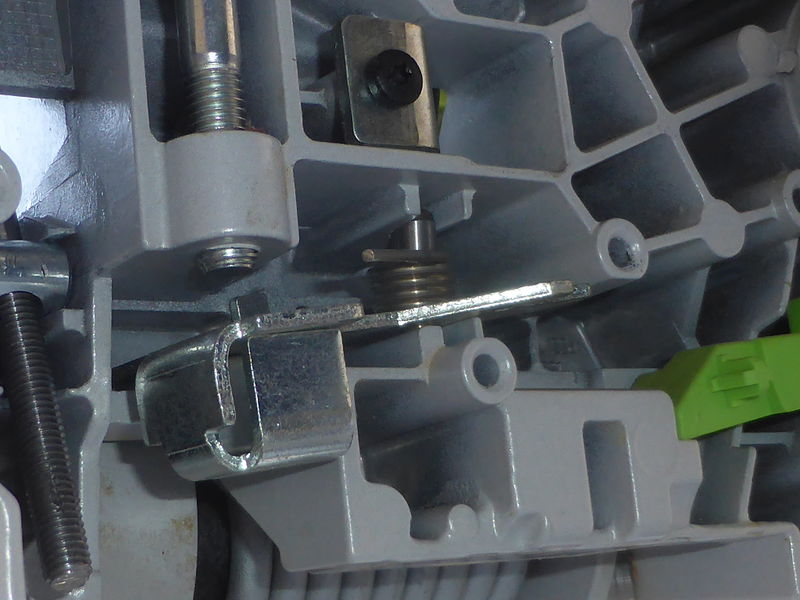

Replace the original lever with your custom made lever.

Once mounted in your miter saw, check if your custom made lever has enough room to move near the motor enclosure.

Mounting hints

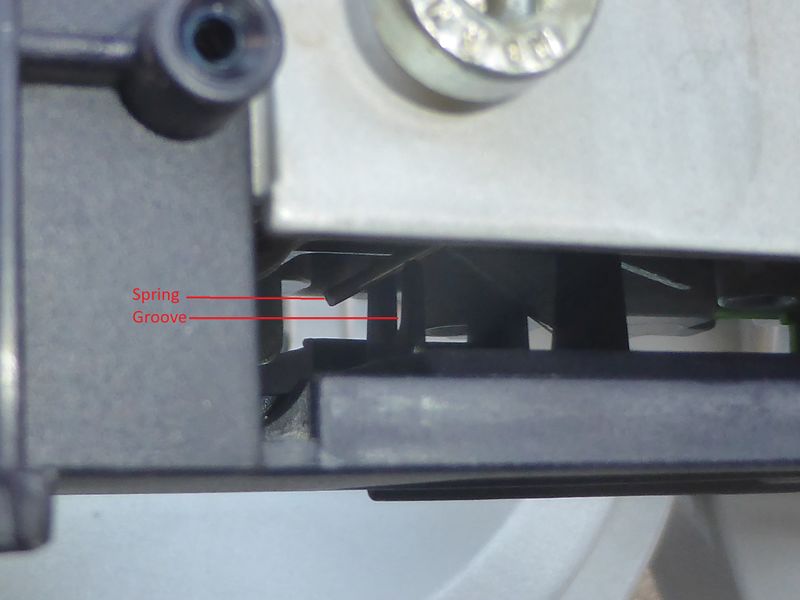

Keep a look on the tall miter latch parts to be sure they are in their correct position.

While positionning the plastic back panel, take care to put the tall miter locking lever spring into it's groove.

Results

With this modding, we now obtain a gorgeous adjustement span from 0 to 93 mm. The dado cut feature of the Kapex becomes now far more versatile.

Other hints and limitations

Barrel nut

You may use the M6 x 1 barrel nut from the existing lever assembly or buy a new part The original part has a 10 mm diameter and 14 mm lenght.

The height adjustment lever has now 3 positions

Once upgraded with your custom part, setting the depth position is slighly different.

For adjustement limit above 50 mm, the 1.4 lever has to be set into an intermediate position.

Cutting witdh

Another limitation (that already exists on an unmodified Kapex saw) : you won't be able to perform the dado cut in one pass on the full nominal machine width of 305 mm, but 220 mm seems to be reachable. To process wider dado cuts, you need to reverse your workpiece.